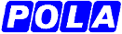

Xbatch manages the feed distribution of 2 feeding supply lines for pullets or breeding sheds through a small weighing hopper (typically 30-50kg) that is loaded by 1 or 2 augers-silos (with the option of mixing feed). The predetermined amount of the feed is “delivered” in its own distribution hopper via 2 line augers ( manages up to 6 valves for the hoppers of the plant A and up to 6 valves for the hoppers of the plant B).

Xbatch manages the feed distribution of 2 feeding supply lines for pullets or breeding sheds through a small weighing hopper (typically 30-50kg) that is loaded by 1 or 2 augers-silos (with the option of mixing feed). The predetermined amount of the feed is “delivered” in its own distribution hopper via 2 line augers ( manages up to 6 valves for the hoppers of the plant A and up to 6 valves for the hoppers of the plant B).

The programmed weight may also be different from the multiple of the capacity of the weigh as the program calculates the amount of exact feed to be distributed for each valve/hopper (with 0.1 Kg resolution).

For example, if you must distribute 40.5 Kg to the hopper A1 and the weigh has a capacity of 30 kg, the program will send the first 30 Kg and then it will send 10.5Kg to complete the distribution.

At the end of each distribution/filling the line auger can operate for a certain time (after the signal of the minimum level of the container of the feed) so that all the feed weighed goes to the hopper and that therefore the line it totally empty.

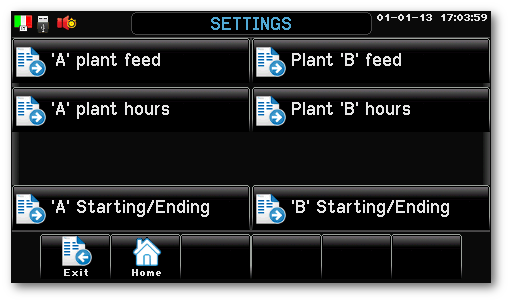

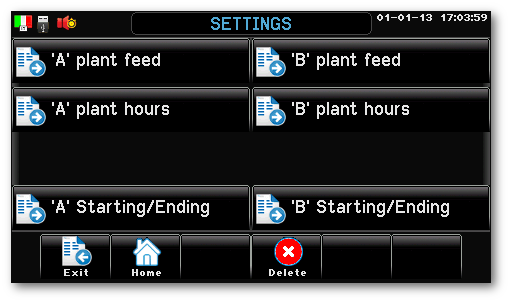

Moreover for each plant (A and B) there are available daily timer for:

- the command of the feeders 1 and 2 - the descent of mangers

- the water Valve and 1 free Timer

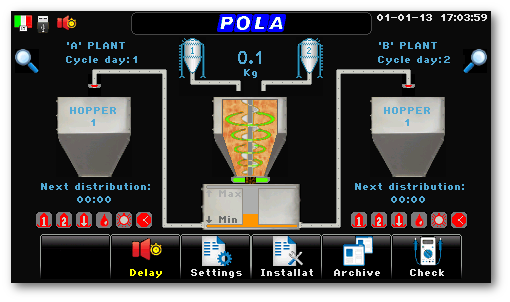

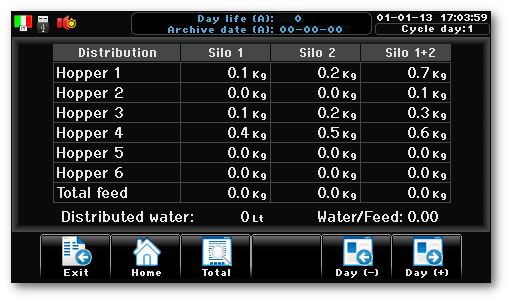

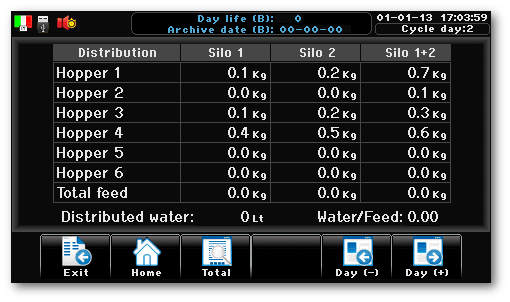

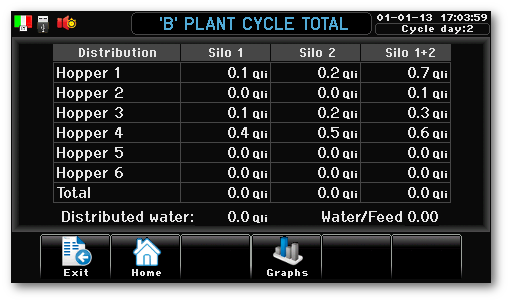

- The Daily archives allows to keep a daily record of all the distributed feed and water for each day of the cycle

|

The connection of the load cells is facilitated with the digital TLC2 that by connecting RS-485 bus can be installed in the shed close to the hopper.

|

|||